OUR PRODUCTS - FIBC'S

Durable and Efficient Bulk Packaging

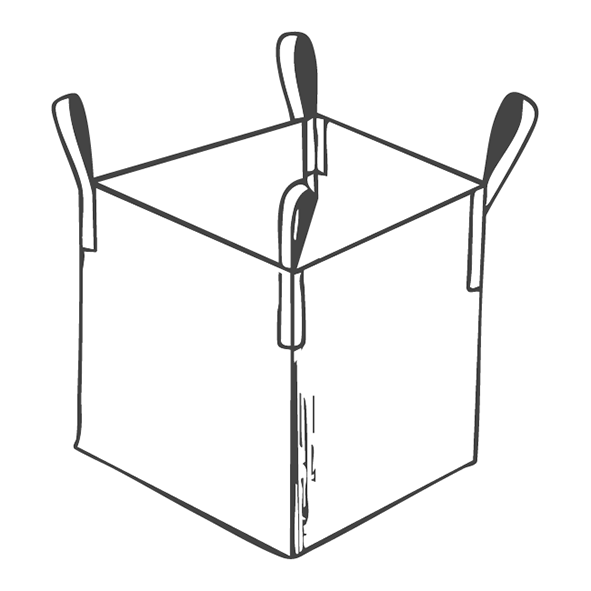

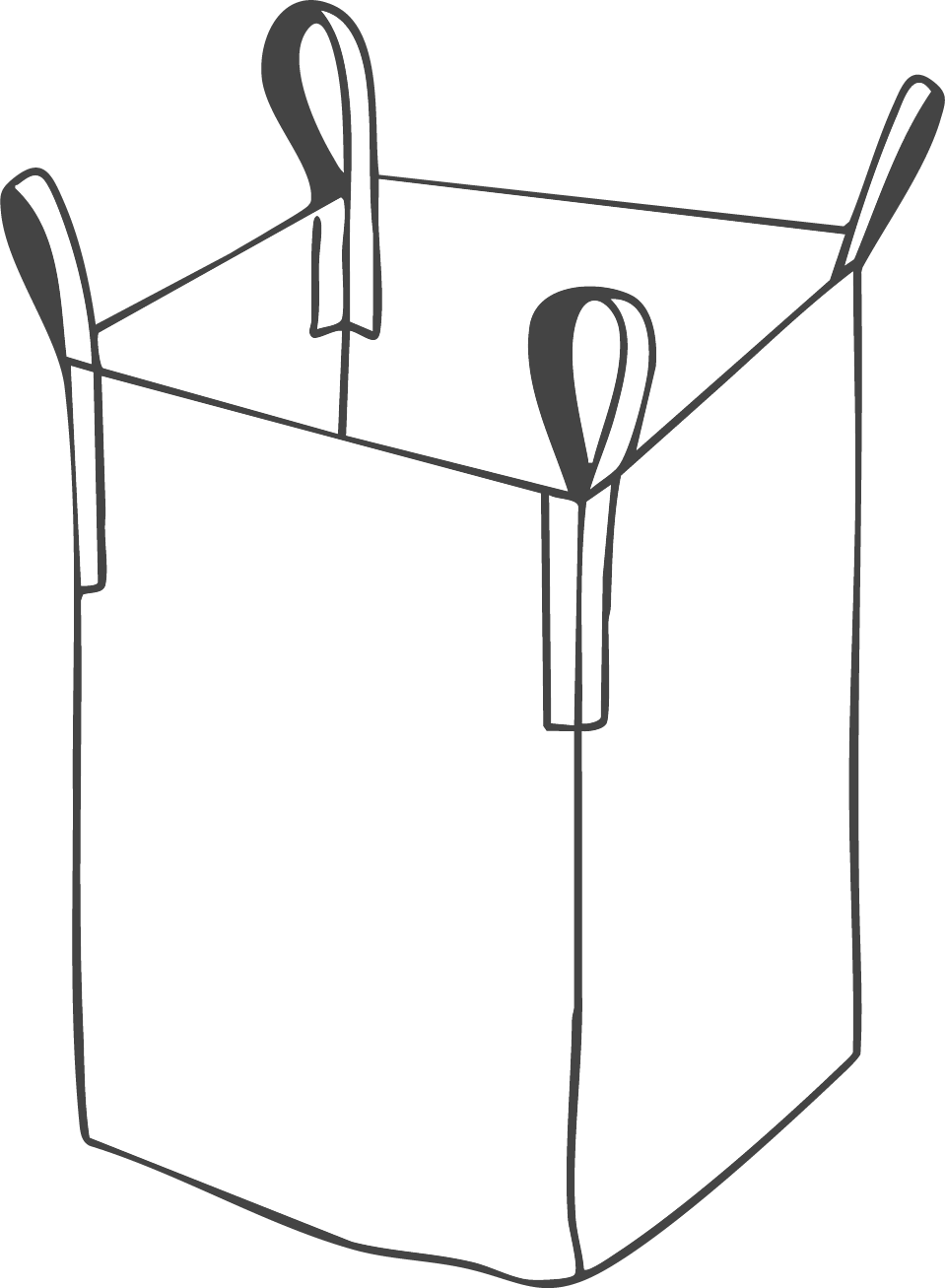

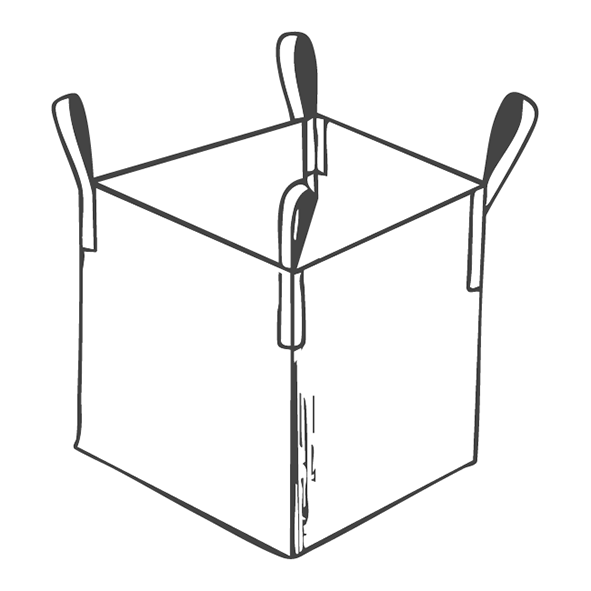

Our Flexible Intermediate Bulk Containers (FIBCs), also known as bulk bags or super sacks, offer a reliable solution for storing and transporting dry, flowable materials. Built for strength and safety, these containers protect your products throughout handling and transit.

Ideal for industries ranging from agriculture to chemicals, FIBCs are a cost-effective way to reduce waste and improve logistics. With features like UV resistance and customisable sizes, they’re designed to meet diverse operational needs.

Their high capacity, ease of handling, and compliance with international safety standards make FIBCs a smart choice for businesses aiming to enhance efficiency and reduce environmental impact.

Flexible Intermediate Bulk Containers (FIBCs)

FIBC Product Features:

• Large storage capacity

• Easy to handle

• UN certified

• Lightweight

• Reusability

• Flexible design

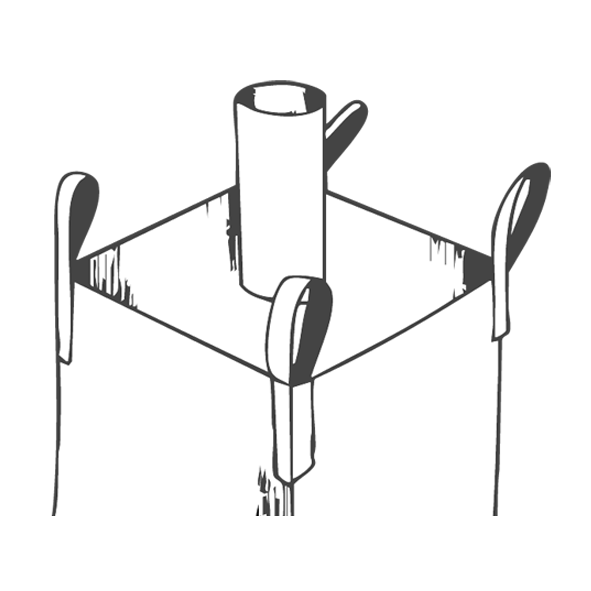

Types of FIBC Bags

FIBC bags are classified into four types—A, B, C, and D—based on their safety features. As materials are loaded or unloaded, static electricity can accumulate due to the movement of the contents. For operations involving flammable or combustible substances, or those conducted in hazardous environments, selecting the appropriate FIBC type is essential to maintain the highest level of safety.

OUR PRODUCTS - FIBC'S

Durable and Efficient Bulk Packaging

Our Flexible Intermediate Bulk Containers (FIBCs), also known as bulk bags or super sacks, offer a reliable solution for storing and transporting dry, flowable materials. Built for strength and safety, these containers protect your products throughout handling and transit.

Ideal for industries ranging from agriculture to chemicals, FIBCs are a cost-effective way to reduce waste and improve logistics. With features like UV resistance and customisable sizes, they’re designed to meet diverse operational needs.

Their high capacity, ease of handling, and compliance with international safety standards make FIBCs a smart choice for businesses aiming to enhance efficiency and reduce environmental impact.

Flexible Intermediate Bulk Containers (FIBCs)

FIBC Product Features:

• Large storage capacity

• Easy to handle

• UN certified

• Lightweight

• Reusability

• Flexible design

TYOPES OF FIBC BAGS

FIBC bags are classified into four types—A, B, C, and D—based on their safety features. As materials are loaded or unloaded, static electricity can accumulate due to the movement of the contents. For operations involving flammable or combustible substances, or those conducted in hazardous environments, selecting the appropriate FIBC type is essential to maintain the highest level of safety.

Product Specifications

MATERIAL

Recycled (20% or 30% Rpp) or 100% Virgin PP, laminated or unlaminated, ventilated, conductive type C, dissipative type D, vento, flame retardant

CONSTRUCTION

U-shape, flat 4 panels, double wall, bag in bag, tubular, 1Looper, 2Looper, Italo type

INLET

Open top, top skirt, top spout, conical top

OUTLET

Flat bottom, bottom spout, bottom skirt, full star bottom, conical

SAFETY FACTOR

5:1, 6:1, 8:1

SAFE WORKING LOAD

From 100 kg to 2500 kg

UV RESISTANT

Yes

DOCUMENT POUCH

A4, A3, A5 or customisable

PRODUCT LENGTH

90 cm, 95cm, 100cm, 110cm + fully customisable

PRODUCT WIDTH

90 cm, 95cm, 100cm, 110cm + fully customisable

PRODUCT HEIGHT

Fully customisable

FABRIC COLOUR

White

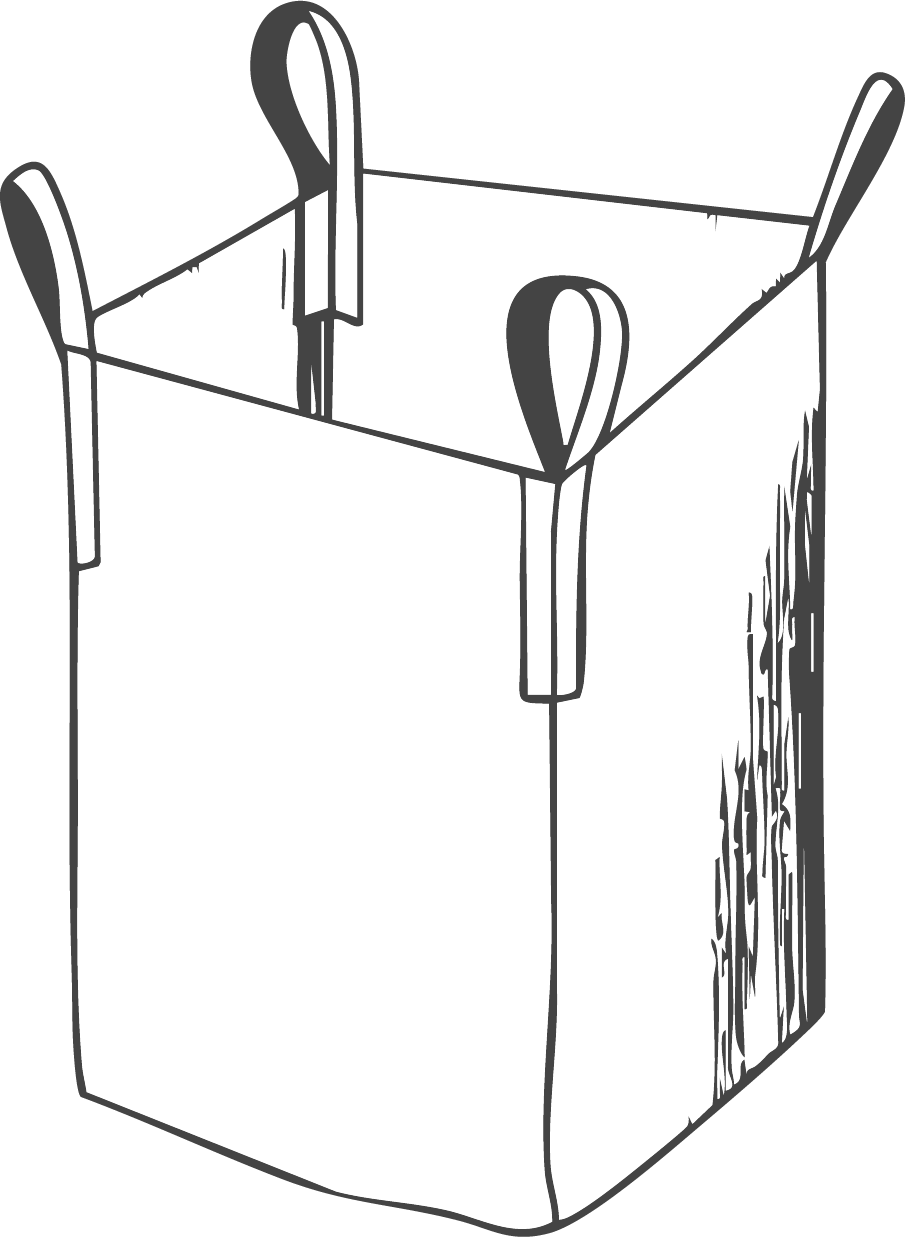

Type A FIBC Bags

Type A FIBC's are made from plain polypropylene and offer no protection against static electricity. They are intended for use in environments free from flammable gases, vapours, or combustible materials, making them appropriate only for handling non-hazardous products in static-free conditions.

Best Suited For:

• Transporting non-hazardous, non-combustible materials

Not Recommended For:

• Use in areas containing flammable gases, vapours, or combustible substances

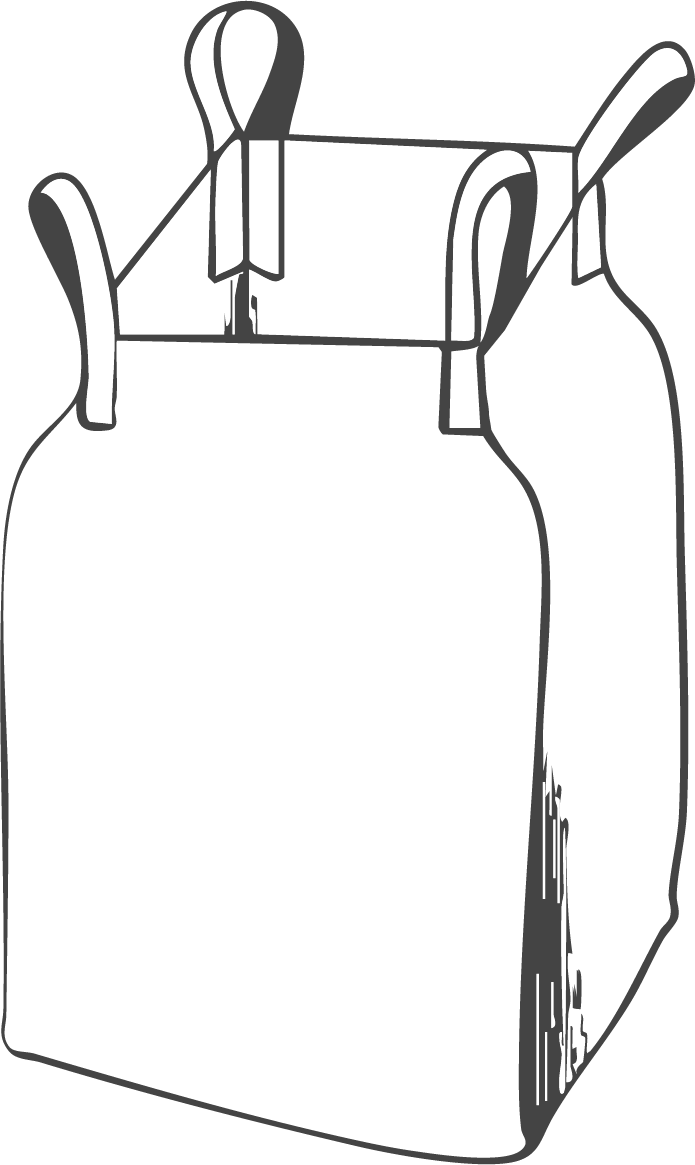

Type B FIBC Bags

Type B FIBC's are constructed from materials with low breakdown voltage to help prevent propagating brush discharges. While they offer some protection against static-related hazards, they do not dissipate static electricity and are not classified as antistatic. Therefore, they are unsuitable for environments containing flammable gases or solvent vapours.

Best Suited For:

• Transporting dry, flammable powders in areas free of explosive atmospheres

Not Recommended For:

• Use near flammable gases or solvent vapours

• Situations requiring antistatic properties or charge dissipation

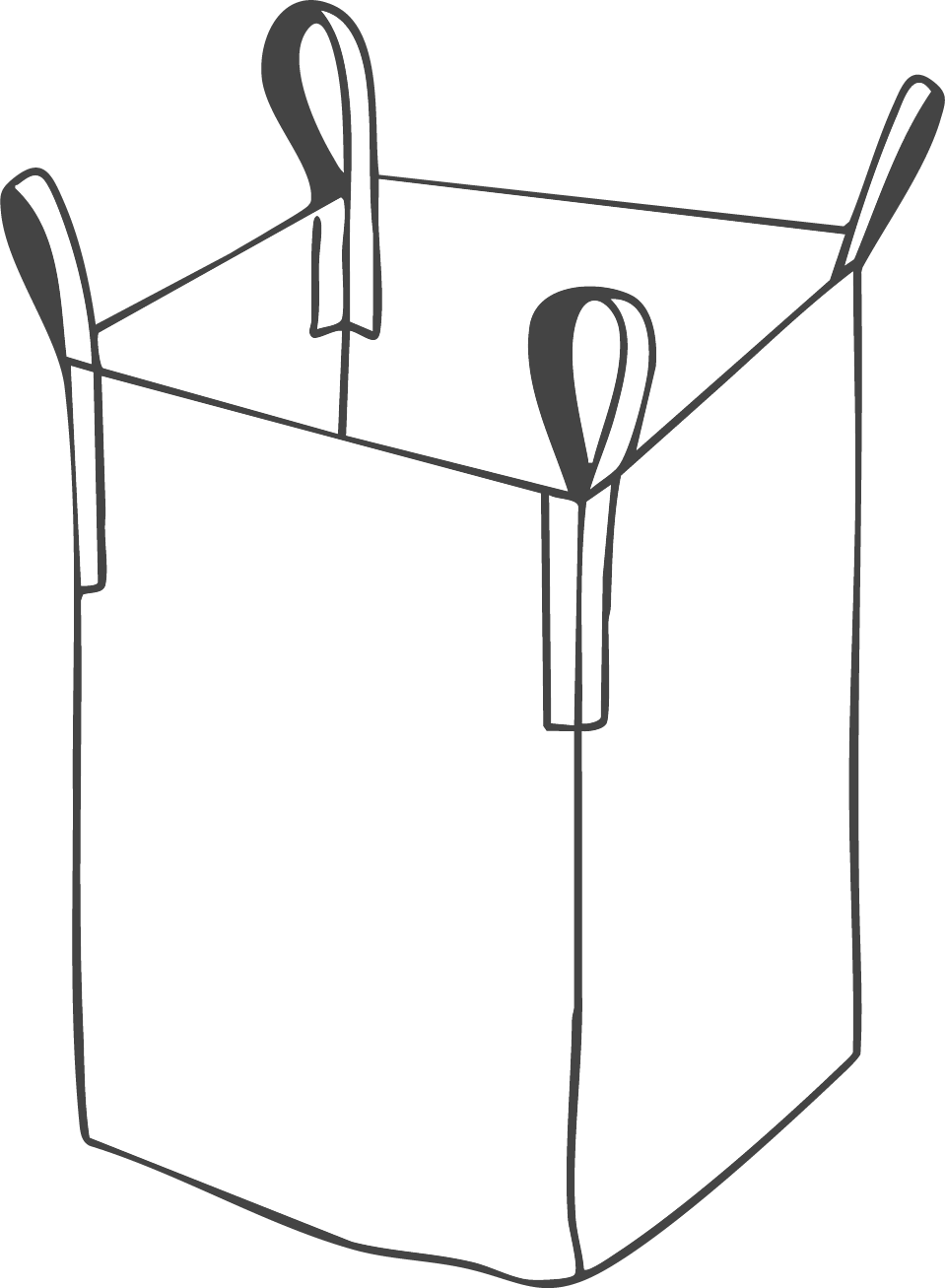

Type C FIBC Bags

Type C FIBC's, also called conductive or groundable bags, are made from polypropylene interwoven with conductive threads in a grid pattern. These threads must be connected to a reliable grounding point during use to safely discharge static electricity. When grounded correctly, Type C bags are suitable for transporting flammable materials in explosive or high-risk environments.

Best Suited For:

• Moving flammable powders

• Operations involving combustible dusts, gases, or vapours

Not Recommended For:

• Use in settings where proper grounding cannot be guaranteed

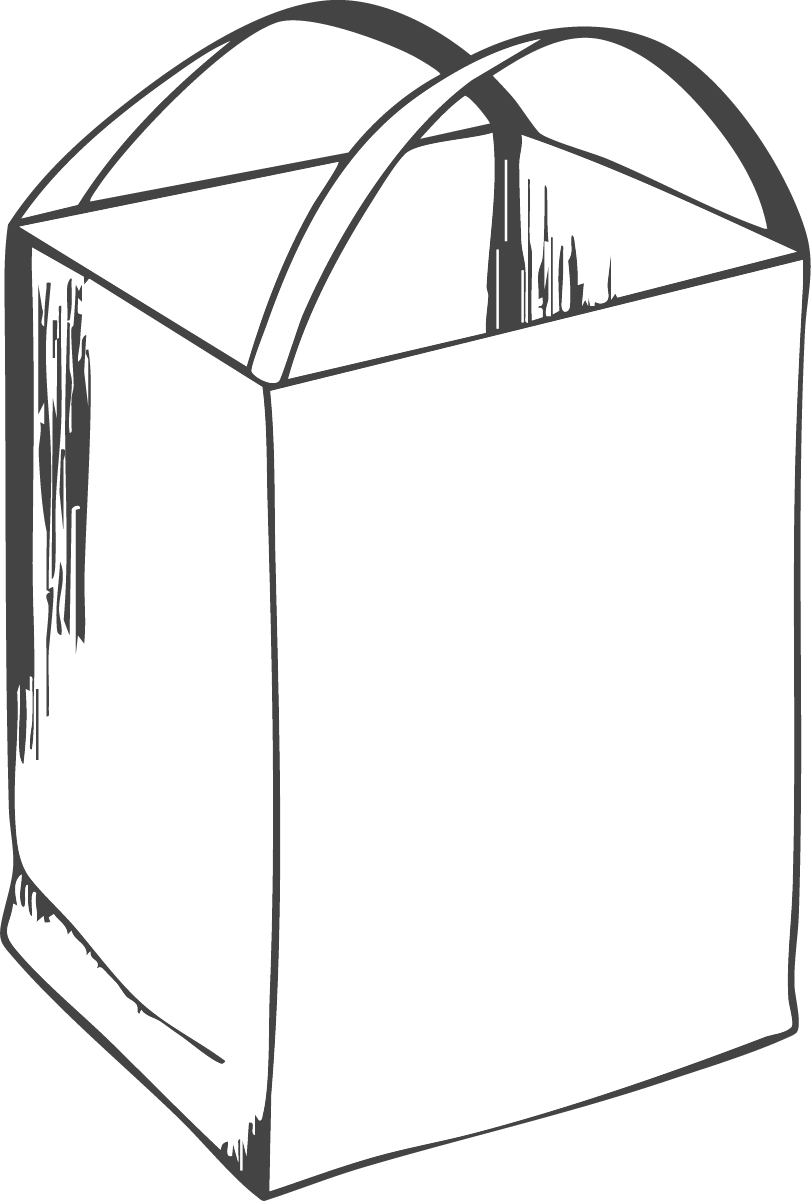

Type D FIBC Bags

Type D FIBC's are made from antistatic, static-dissipative fabric designed to prevent sparks and brush discharges without the need for grounding. Often manufactured using CHROHMIQ or similar materials, these bags provide strong protection against static hazards, making them ideal for use in sensitive or hard-to-ground environments.

Best Suited For:

• Transporting flammable powders

• Use in areas with combustible gases, vapours, or dust

Not Recommended For:

• Applications requiring grounded conductive threads or yarns

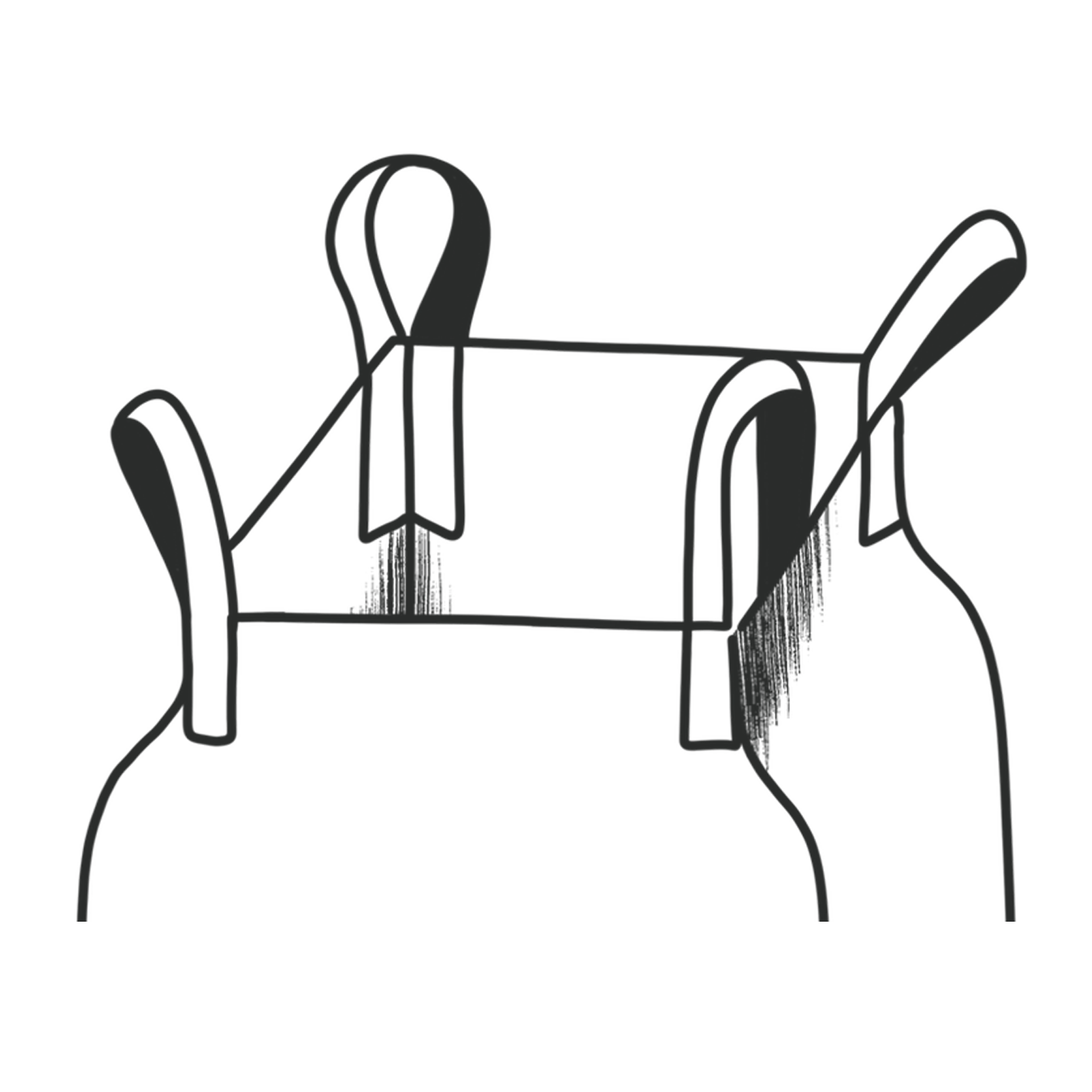

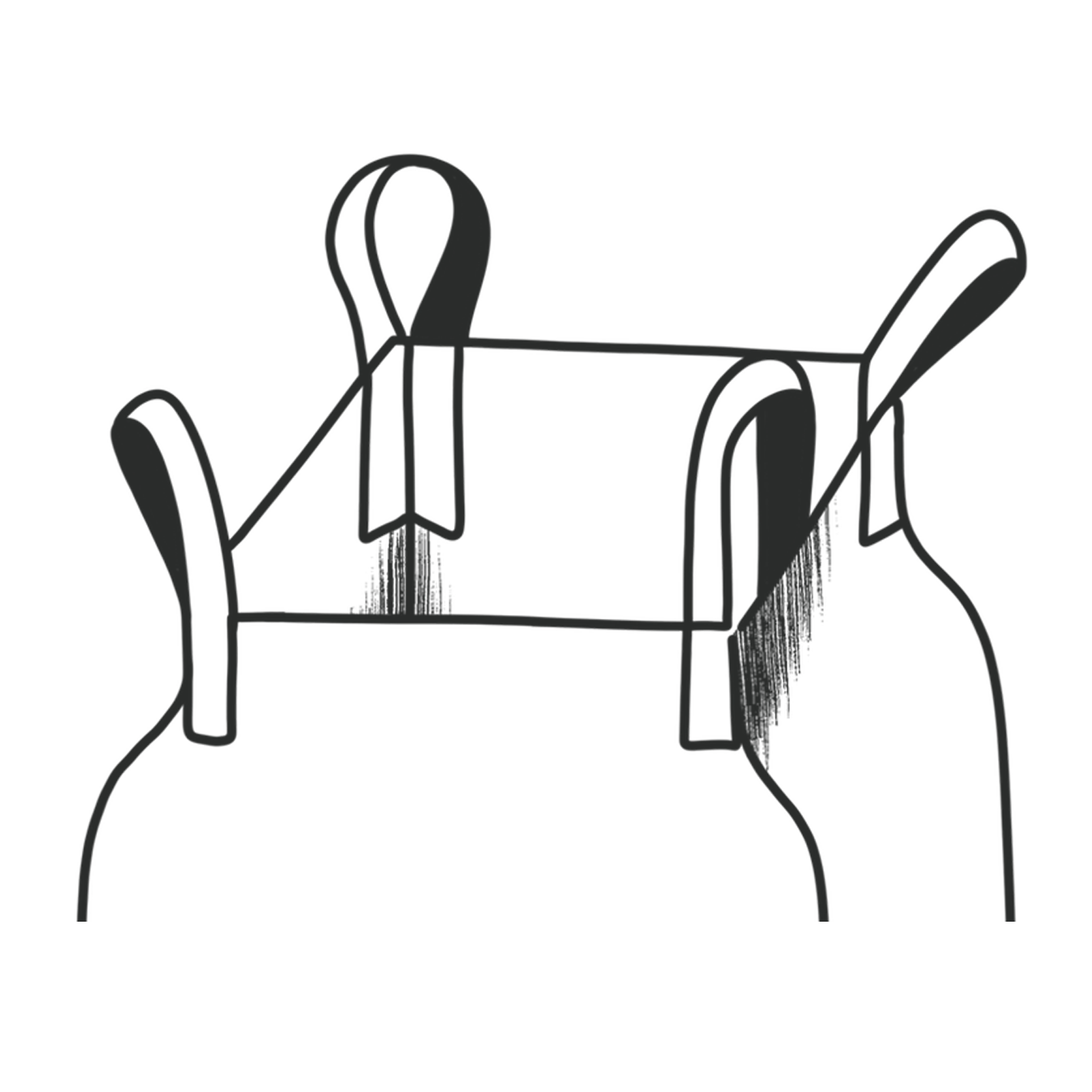

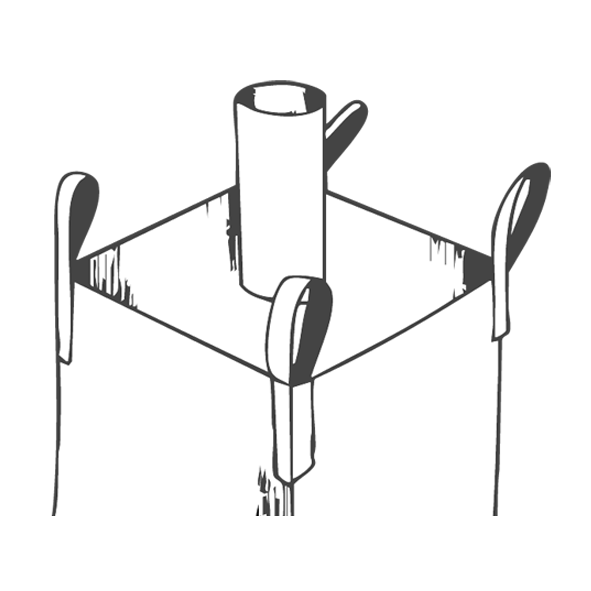

Top Construction Options

FIBCs can be better adapted to specific applications with the use of various filling options.

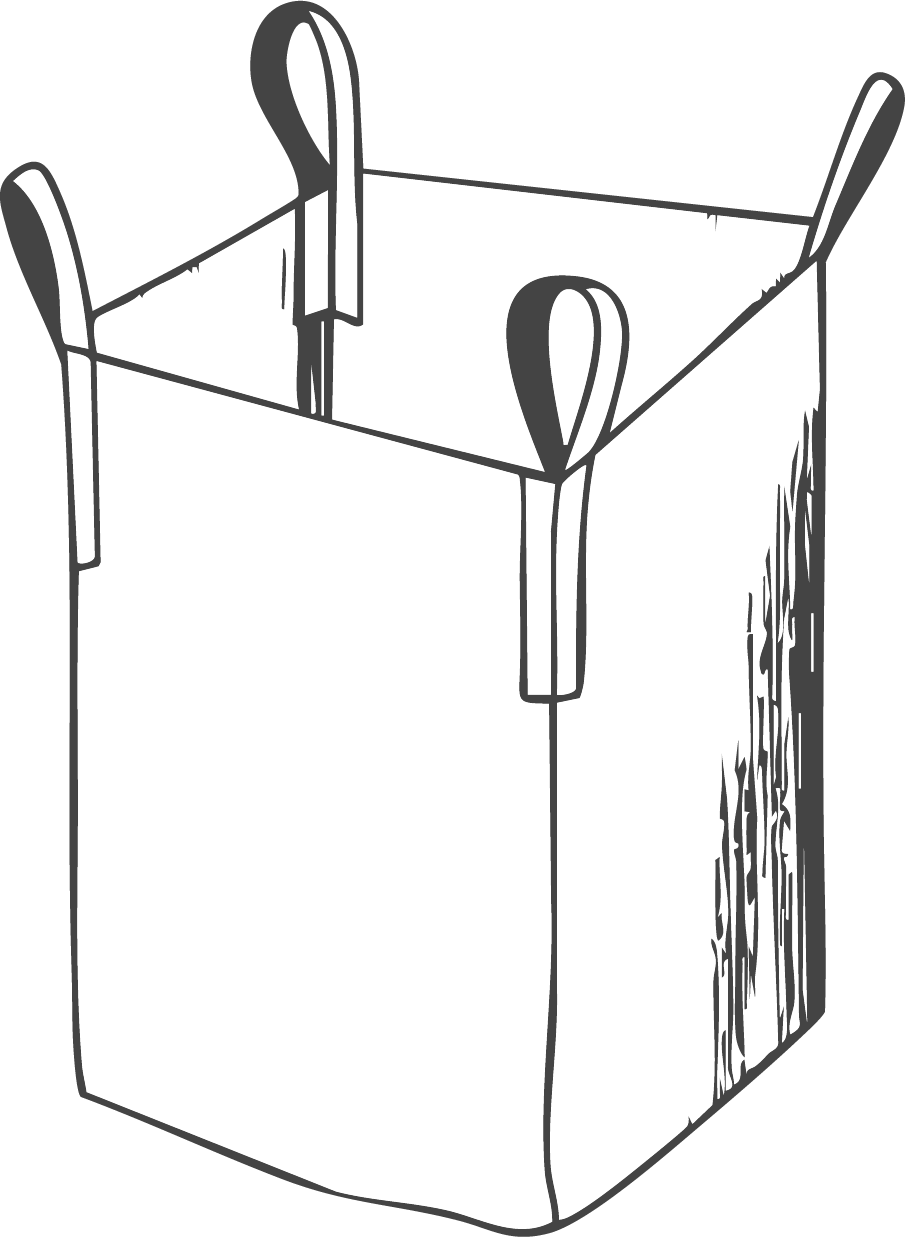

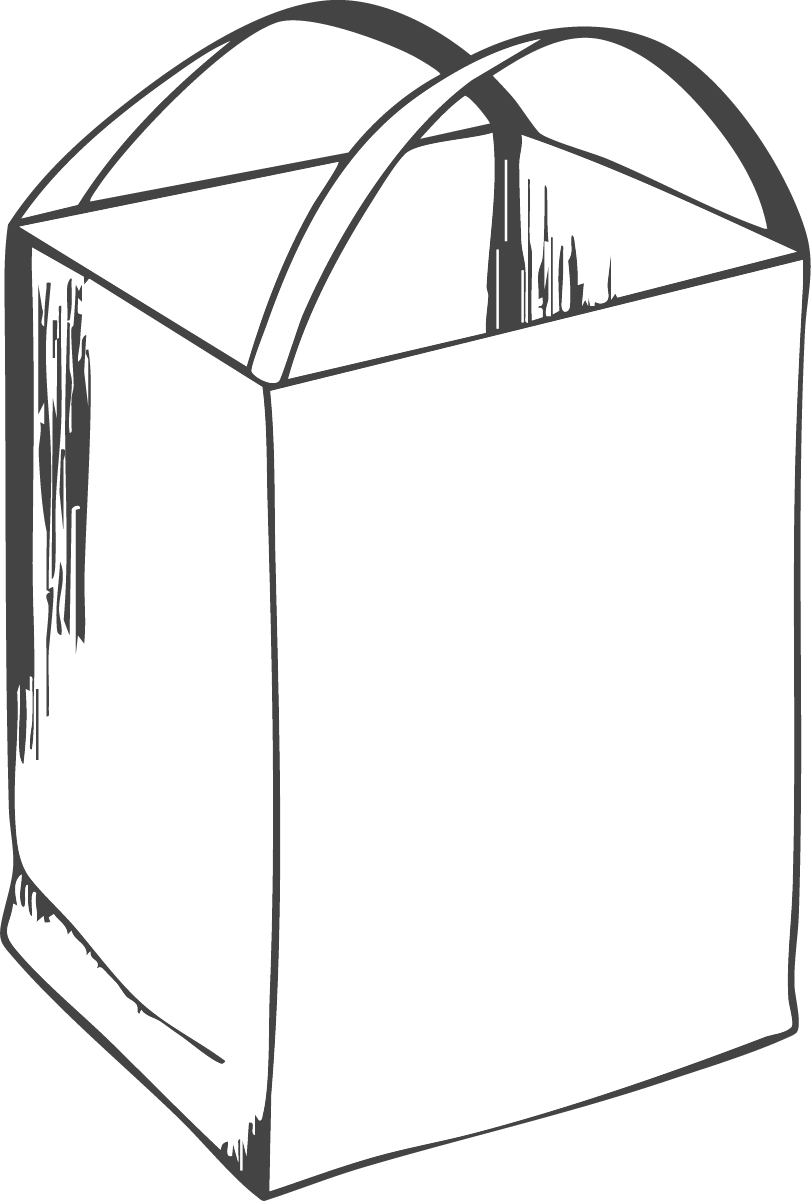

Open Top

The open top allows for easy access, offering filling convenience.

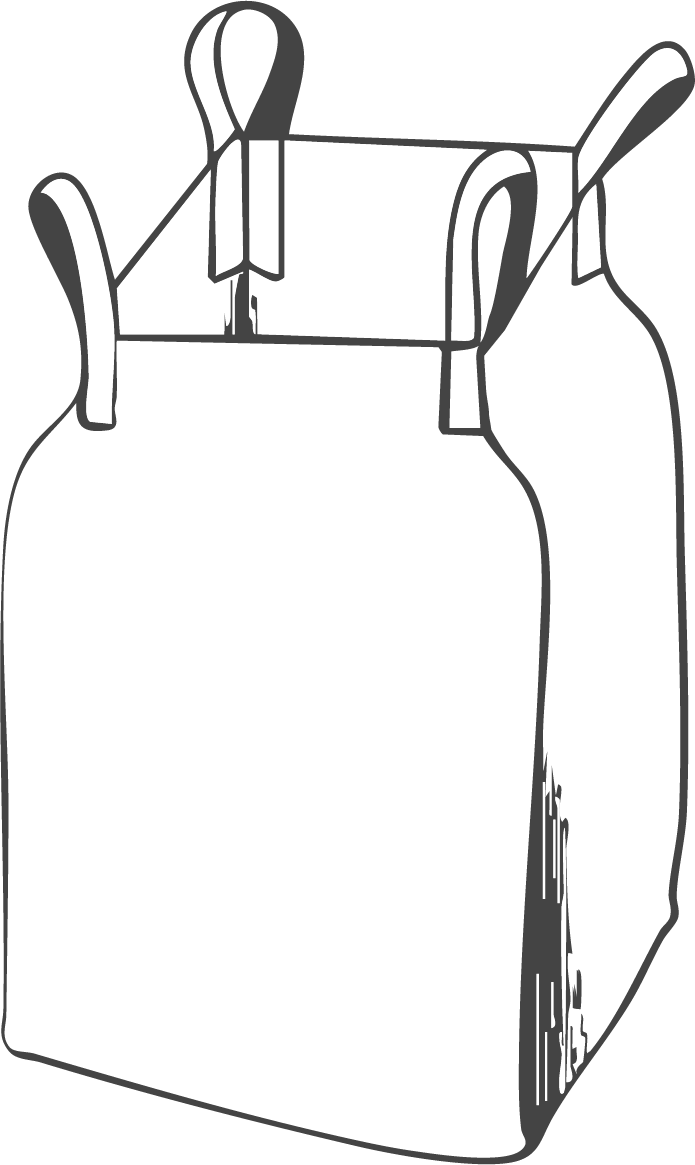

Duffle Top

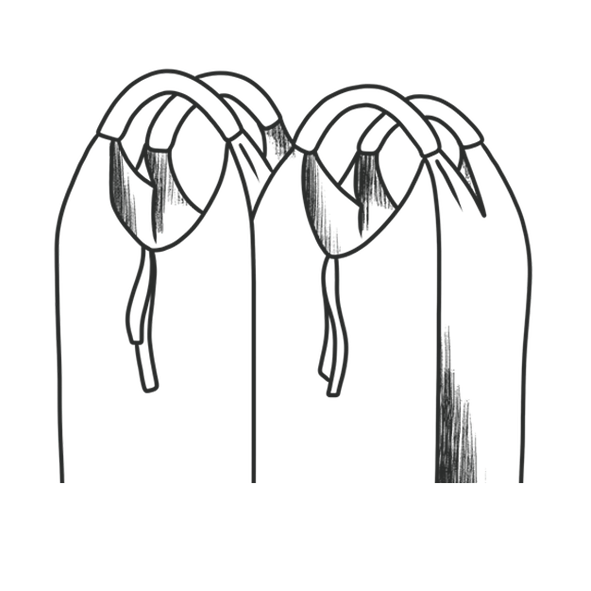

A lightweight fabric panel

at the top, offering filling convenience and making it

easy to close the bag.

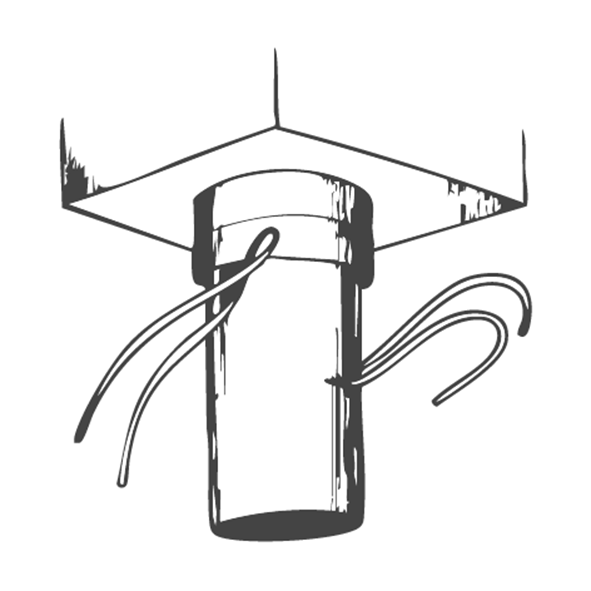

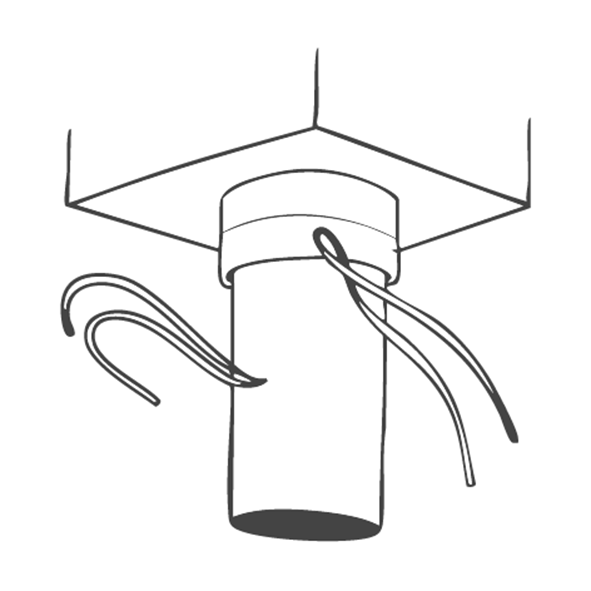

Spout Top

A cylindrical spout

integrated into the top

panel, designed for precise

filling applications.

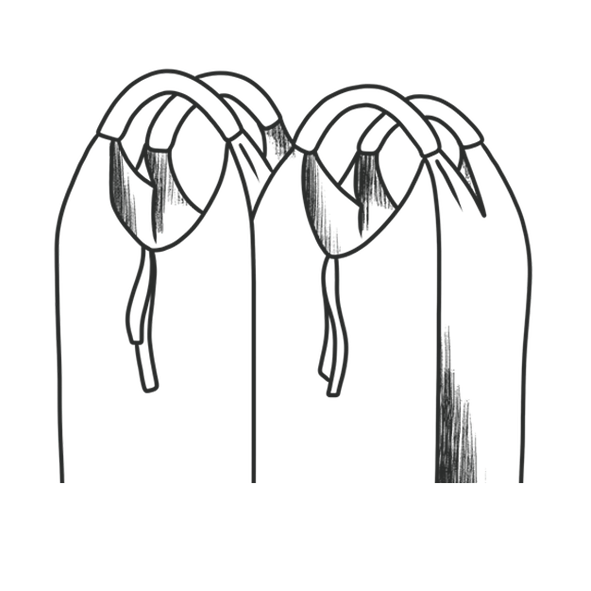

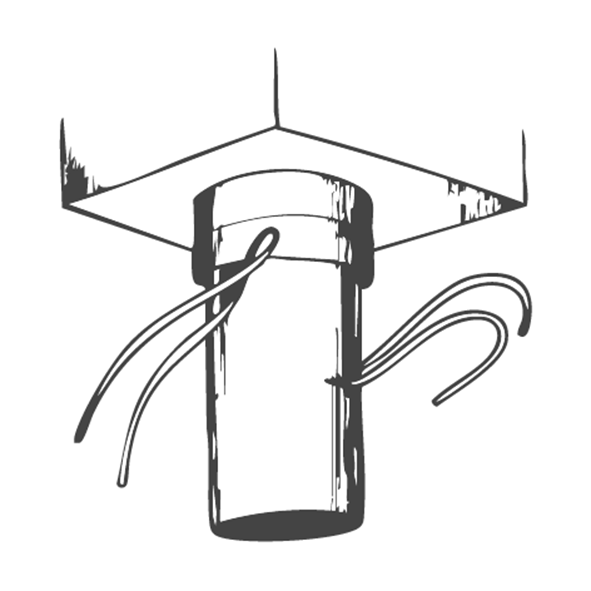

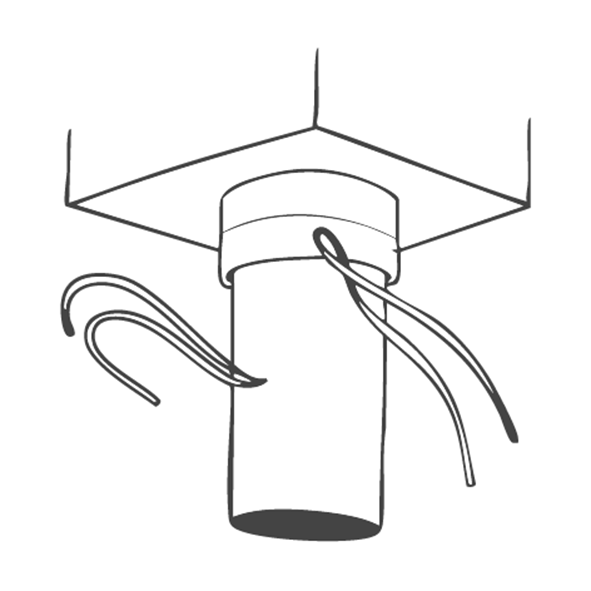

Bottom Construction Options

FIBCs can be better adapted to specific applications with the use of various discharging options.

Plain Bottom

A basic bottom design with no built-in discharge mechanism.

Discharge Spout

A standard spout at the bottom, enabling easy removal of the bag's contents.

Conical Discharge Spout

A discharge spout with a conical shape, designed for efficient and precise content removal.

How to Select the Most Suitable

Flexible Intermediate Bulk Container (FIBC) Bags

FIBC bags come in various types, and their features can significantly influence their performance in different applications.

For example, specific coatings can enhance functionality based on your storage and transport needs.

Uncoated FIBCs may allow fine particles, such as powders, to escape through the fabric and seams. This can be beneficial in applications

where airflow is needed, but they provide minimal defence against moisture and external contaminants.

Coated FIBCs, on the other hand, include an additional polypropylene layer that helps seal the fabric and prevent leakage. This extra protection makes them well-suited for holding fine substances like powders or chemicals, while also helping to reduce product loss.

Please be sure to download the FIBC Handling Guide by clicking the button below.

Product Specifications

MATERIAL

Recycled (20% or 30% Rpp) or 100% Virgin PP, laminated or unlaminated, ventilated, conductive type C, dissipative type D, vento, flame retardant

CONSTRUCTION

U-shape, flat 4 panels, double wall, bag in bag, tubular, 1Looper, 2Looper, Italo type

INLET

Open top, top skirt, top spout, conical top

OUTLET

Flat bottom, bottom spout, bottom skirt, full star bottom, conical

SAFETY FACTOR

5:1, 6:1, 8:1

SAFE WORKING LOAD

From 100 kg to 2500 kg

UV RESISTANT

Yes

DOCUMENT POUCH

A4, A3, A5 or customisable

PRODUCT LENGTH

90 cm, 95cm, 100cm, 110cm + fully customisable

PRODUCT WIDTH

90 cm, 95cm, 100cm, 110cm + fully customisable

PRODUCT HEIGHT

Fully customisable

FABRIC COLOUR

White

TYPE A FIBC BAGS

Type A FIBC's are made from plain polypropylene and offer no protection against static electricity. They are intended for use in environments free from flammable gases, vapours, or combustible materials, making them appropriate only for handling non-hazardous products in static-free conditions.

Best Suited For:

• Transporting non-hazardous, non-combustible materials

Not Recommended For:

• Use in areas containing flammable gases, vapours, or combustible substances

TYPE B FIBC BAGS

Type B FIBC's are constructed from materials with low breakdown voltage to help prevent propagating brush discharges. While they offer some protection against static-related hazards, they do not dissipate static electricity and are not classified as antistatic. Therefore, they are unsuitable for environments containing flammable gases or solvent vapours.

Best Suited For:

• Transporting dry, flammable powders in areas free of explosive atmospheres

Not Recommended For:

• Use near flammable gases or solvent vapours

• Situations requiring antistatic properties or charge dissipation

TYPE C FIBC BAGS

Type C FIBC's, also called conductive or groundable bags, are made from polypropylene interwoven with conductive threads in a grid pattern. These threads must be connected to a reliable grounding point during use to safely discharge static electricity. When grounded correctly, Type C bags are suitable for transporting flammable materials in explosive or high-risk environments.

Best Suited For:

• Moving flammable powders

• Operations involving combustible dusts, gases, or vapours

Not Recommended For:

• Use in settings where proper grounding cannot be guaranteed

TYPE D FIBC BAGS

Type D FIBC's are made from antistatic, static-dissipative fabric designed to prevent sparks and brush discharges without the need for grounding. Often manufactured using CHROHMIQ or similar materials, these bags provide strong protection against static hazards, making them ideal for use in sensitive or hard-to-ground environments.

Best Suited For:

• Transporting flammable powders

• Use in areas with combustible gases, vapours, or dust

Not Recommended For:

• Applications requiring grounded conductive threads or yarns

Top Construction Options

FIBCs can be better adapted to specific applications with the use of various filling options.

Open Top

The open top allows for easy access, offering filling convenience.

Duffle Top

A lightweight fabric panel

at the top, offering filling convenience and making it

easy to close the bag.

Spout Top

A cylindrical spout

integrated into the top

panel, designed for precise

filling applications.

Bottom Construction Options

FIBCs can be better adapted to specific applications with the use

of various discharging options.

Plain Bottom

A basic bottom design with no built-in discharge mechanism.

Discharge Spout

A standard spout at the bottom, enabling easy removal of the bag's contents.

Conical Discharge Spout

A discharge spout with a conical shape, designed for efficient and precise content removal.

How to Select the Most Suitable Flexible Intermediate Bulk

Container (FIBC) Bags

FIBC bags come in various types, and their features can significantly influence their performance in different applications. For example, specific coatings can enhance functionality based on your storage and transport needs.

Uncoated FIBCs may allow fine particles, such as powders, to escape through the fabric and seams. This can be beneficial in applications where airflow is needed, but they provide minimal defence against moisture and external contaminants.

Coated FIBCs, on the other hand, include an additional polypropylene layer that helps seal the fabric and prevent leakage. This extra protection makes them well-suited for holding fine substances like powders or chemicals, while also helping to reduce product loss.

Please be sure to download the FIBC Handling Guide by clicking the button below.

We specialise in the packaging of industrial, agricultural, mineral and mining, food grade and pharmaceutical products.

We specialise in the packaging of industrial, agricultural, mineral

and mining, food grade and pharmaceutical products.